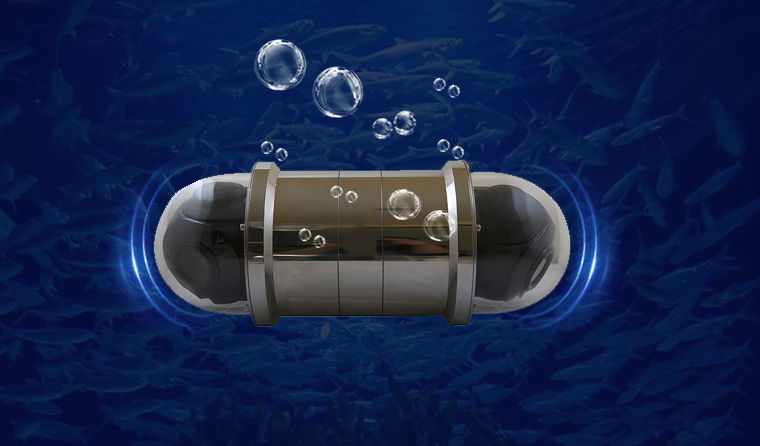

The prevention of seawater corrosion for underwater aquaculture cameras can be approached from the following aspects:

-

Optimized Sealing Design: High-precision sealing devices, such as O-rings and sealing strips, are used to ensure complete isolation between the internal camera and the external seawater environment, preventing seawater infiltration. Simultaneously, attention should be paid to avoiding gaps and dead corners in the design to reduce the possibility of seawater residue and corrosion.

-

Adoption of Cathodic Protection Technology: This can be achieved through the sacrificial anode protection method or the impressed current protection method. The sacrificial anode protection method uses metals with high electrochemical activity (e.g., magnesium, zinc, aluminum) as anodes, which corrode in seawater to protect the camera's metal housing. The impressed current protection method applies an external DC power supply to the metal structure of the camera to be protected, making the metal structure a cathode and thereby inhibiting corrosion.

-

Selection of Appropriate Installation Location and Method: Try to avoid installing the camera in locations where seawater flows too fast, salt concentration is too high, or there is a large amount of sediment—these conditions can easily cause wear and corrosion to the camera. Meanwhile, ensure the camera is firmly installed to prevent seal failure or component damage due to water flow impact and other factors.

-

Regular Maintenance and Upkeep: Regularly inspect and clean the camera, and promptly remove dirt, salt, and marine organism attachments from the surface. If wear, coating peeling, or other issues are found on the camera housing, repair or re-spray the coating in a timely manner. In addition, the performance of the sealing devices should be checked regularly; if there are problems such as aging or damage, they should be replaced promptly.