How Do Underwater Aquaculture Cameras Work?

Hits: 769 Time: September 22,2025

The working principle of underwater aquaculture cameras revolves around five core components: underwater environment adaptation, image acquisition, signal transmission, data processing, and power supply. Through the collaboration of multiple components, they achieve real-time monitoring and data feedback of aquaculture waters. The specific working process is as follows:

High water pressure, strong corrosiveness (seawater salt spray), and low visibility in underwater aquaculture scenarios are the primary challenges for cameras. Therefore, their "working foundation" lies in adapting to the environment through specialized designs:

-

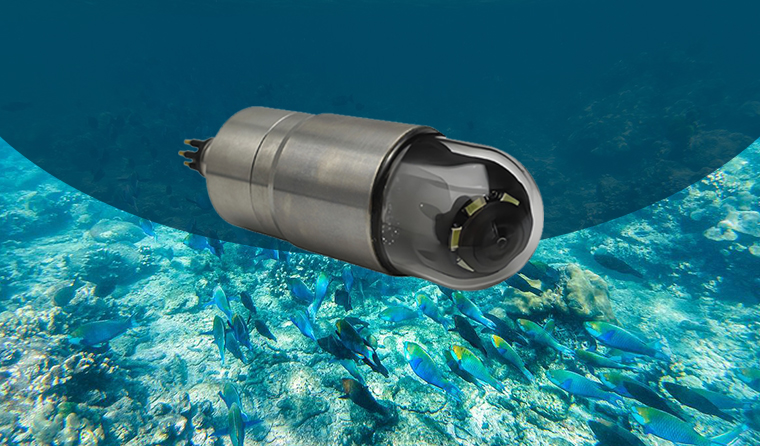

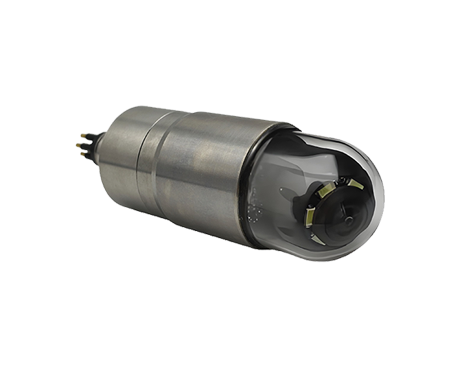

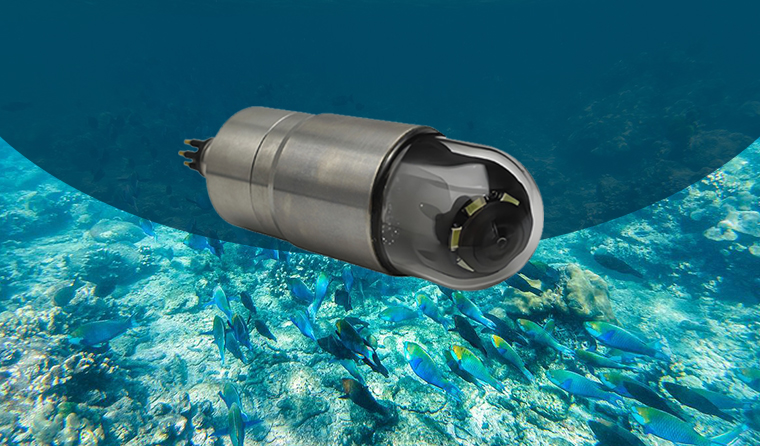

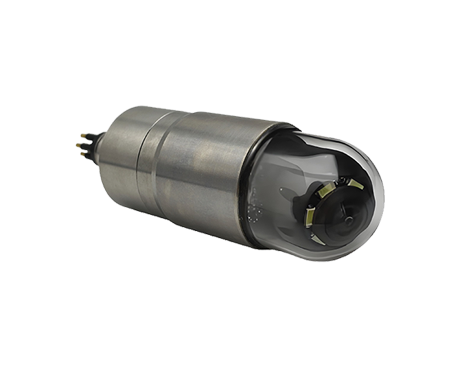

Sealing and Anti-Corrosion Protection: A fully sealed structure (such as O-rings and laser welding technology) is adopted to prevent seawater infiltration. The housing is made of 316L stainless steel, titanium alloy, or anti-corrosion composite materials. Internal electronic components are coated with "three-proof paint" (resistant to salt spray, moisture, and mildew) to avoid corrosion damage.

-

Pressure-Resistant Design: According to the aquaculture water depth (ranging from several meters to dozens of meters), the housing adopts a pressure-resistant structure design (such as a thickened shell and curved pressure-resistant glass) to ensure no deformation or damage under underwater pressure. The lens glass also needs to be pressure-resistant to protect the internal imaging components.

-

Low-Visibility Adaptation: Some cameras are equipped with infrared fill lights (for night or deep-water lightless environments) or white lights (for supplementary lighting in turbid waters). Some high-end models are also equipped with a "fog-penetrating algorithm" to reduce the interference of sediment and plankton in the water on imaging.

This is the "perceptual core" of the camera, which converts underwater scenes into electrical signals through optical components:

-

Lens Assembly: Underwater-specific wide-angle or zoom lenses are used (wide-angle lenses can expand the monitoring range, suitable for scenarios such as aquaculture cages and ponds). The lens glass is treated with an anti-reflection coating to reduce the reflection and refraction of light by water and improve light transmittance.

-

Image Sensor (CMOS/CCD): The underwater light captured by the lens (natural light or light from fill lights) is focused on the image sensor, which converts the optical signal into an analog electrical signal. Currently, most mainstream models use CMOS sensors, which have the advantages of low power consumption and high frame rate (suitable for dynamic monitoring, such as fish swimming). CCD sensors are used in some high-precision scenarios, which produce lower image noise.

-

Analog-to-Digital Conversion (ADC): The analog electrical signal output by the sensor is converted into a digital signal through an "analog-to-digital converter" to prepare for subsequent processing and transmission.

The digital signals collected underwater need to be transmitted to the above-water control system or the cloud, which is the core of realizing "remote monitoring".

For more information about underwater aquaculture camera, please visit the homepage.