In the marine aquaculture industry, underwater cameras, as key equipment for monitoring the growth status of aquaculture organisms and observing changes in the water environment, their stable operation is directly related to the efficiency and safety of aquaculture production. However, the corrosiveness of the seawater environment to underwater aquaculture cameras cannot be ignored, and even becomes a major cause of equipment failure if effective protective measures are not taken.

The reason why seawater is highly corrosive lies in its special chemical composition and physical properties. Seawater is a complex electrolyte solution, which not only contains about 3.5% salt substances (mainly sodium chloride, followed by magnesium chloride, calcium chloride, etc.), but also dissolves a certain amount of oxygen, carbon dioxide and various trace elements. This composition provides the basic conditions for electrochemical corrosion: when the metal components of the camera come into contact with seawater, galvanic cells will be formed between different metals (or metals and non-metallic impurities), and the anode metal undergoes oxidation reaction and is gradually consumed, leading to rust, damage and other phenomena. For example, a fixed bracket made of ordinary steel may lose its load-bearing capacity due to corrosion within a few months if it is immersed in seawater for a long time; even relatively corrosion-resistant metals such as copper and aluminum will gradually form corrosion products under the long-term action of seawater, affecting the mechanical properties and electrical connection stability of the components.

In addition to electrochemical corrosion, microorganisms in seawater will also accelerate the corrosion process of the camera, a phenomenon known as biological corrosion. Microorganisms such as bacteria, fungi and algae in seawater will attach to the surface of the camera's housing, lens, interface, etc., forming a dense biofilm. The biofilm not only blocks the lens and blurs the shooting image, but also the microbial metabolic activities inside produce corrosive products such as acidic substances and sulfides, which destroy the oxide protective film on the metal surface and accelerate the rate of electrochemical corrosion. At the same time, the existence of biofilm will also cause local oxygen concentration difference, forming a concentration cell, which further promotes the occurrence of corrosion reaction. For example, if biofilm adheres to the connection between the camera lens and the housing, it may cause the sealing rubber strip to fail due to corrosion, and then seawater leakage may occur, damaging the internal circuit motherboard, image sensor and other core components.

For underwater aquaculture cameras, the harm caused by seawater corrosion is multifaceted. In terms of equipment performance, corrosion will lead to the decline of dimensional accuracy of metal parts and the increase of fit clearance, affecting the focusing, rotation and other functions of the camera; after the circuit interface is corroded, problems such as poor contact and signal transmission interruption may occur, resulting in stuck or lost monitoring images. In terms of service life, the service life of cameras without professional anti-corrosion treatment in seawater is usually only 1-2 years, while the service life of equipment with anti-corrosion design can be extended to 5-8 years, with a significant difference between the two. In terms of aquaculture production, if the camera fails to work normally due to corrosion, it will make it difficult for breeders to grasp the feeding, growth, health status of aquaculture organisms and the environmental parameters such as dissolved oxygen, water temperature and water quality in real time, which may miss the best feeding opportunity and disease prevention and control opportunity, resulting in economic losses.

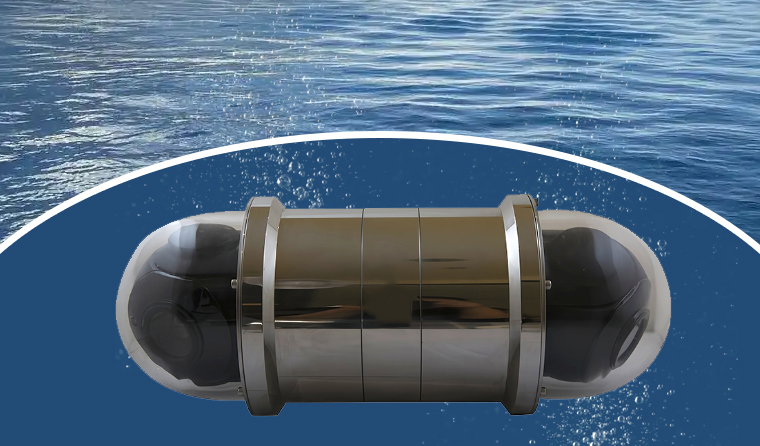

In order to deal with the corrosion problem of seawater on underwater aquaculture cameras, a series of targeted anti-corrosion design and technical measures are usually adopted in the industry. In terms of material selection, metal materials with excellent seawater corrosion resistance such as titanium alloy, 316L stainless steel and Hastelloy are preferred to make housings, brackets and other components; for non-metallic components, such as seals and cable sheaths, high molecular materials with aging resistance and chemical corrosion resistance such as fluororubber and polytetrafluoroethylene are selected. In terms of surface treatment, metal parts are electroplated (such as chrome plating, nickel plating), sprayed (such as polyurea coating, ceramic coating), passivated, etc., to form an isolation layer on their surface to prevent direct contact between seawater and metal. In terms of structural design, a fully sealed structure is adopted to prevent seawater from entering the interior of the equipment; drainage holes and exhaust holes are set to prevent seal failure caused by pressure difference between inside and outside the equipment; waterproof connectors are used at the interface, and special waterproof sealant is applied. In addition, regular cleaning and maintenance of the camera to remove biofilm and corrosion products on the surface is also an important means to delay corrosion and extend the service life of the equipment.

To sum up, seawater has strong corrosiveness to underwater aquaculture cameras. Its corrosion mechanisms include electrochemical corrosion and biological corrosion, which will have a serious impact on the performance, service life of the equipment and aquaculture production. Therefore, in the selection, design and use of underwater aquaculture cameras, the problem of seawater corrosion must be fully emphasized, and effective anti-corrosion measures must be taken to ensure the stable operation of the equipment and provide reliable technical support for the intelligent and refined development of the marine aquaculture industry.

For more information about underwater aquaculture camera, please visit the homepage.