In scenarios such as deep-water aquaculture, cage aquaculture, and deep-sea experimental aquaculture, underwater pressure-resistant cameras are core equipment that breaks through water depth limitations and enables underwater environment and biological monitoring. The water depth in aquaculture varies greatly, from a few meters in shallow ponds to tens of meters in deep-sea cages, and even more than 100 meters in some special aquaculture scenarios. This places extremely high demands on the structural strength and pressure resistance of underwater pressure-resistant cameras. Selecting a suitable underwater pressure-resistant camera requires scientific judgment based on pressure resistance performance as the core, combined with the water depth characteristics of the aquaculture scenario, monitoring needs, and comprehensive equipment performance.

The core indicator for judging underwater pressure-resistant cameras is rated working water depth and pressure resistance, which directly determines whether the equipment can operate safely in the target aquaculture environment. The water pressure corresponding to different water depths varies significantly—the pressure at 10 meters water depth is approximately 1 standard atmosphere, and the pressure increases correspondingly for every additional 10 meters of water depth. Therefore, when selecting, it is necessary to clarify the maximum water depth of the aquaculture scenario and choose equipment with a rated working water depth greater than the actual aquaculture water depth, leaving a certain safety margin. For example, in cage aquaculture with 20 meters water depth, priority should be given to underwater pressure-resistant cameras with a rated working water depth of 30 meters or more to avoid shell rupture, lens damage, or internal circuit water ingress due to excessive water pressure. The pressure resistance of the equipment is closely related to the shell material and sealing process. Underwater pressure-resistant cameras using titanium alloy, high-strength stainless steel, or special engineering ceramic shells have much better pressure resistance than ordinary metal materials; and multiple silicone sealing rings combined with laser welding sealing technology can further enhance the waterproof and pressure-resistant sealing of the equipment, effectively resisting long-term underwater pressure damage to the equipment.

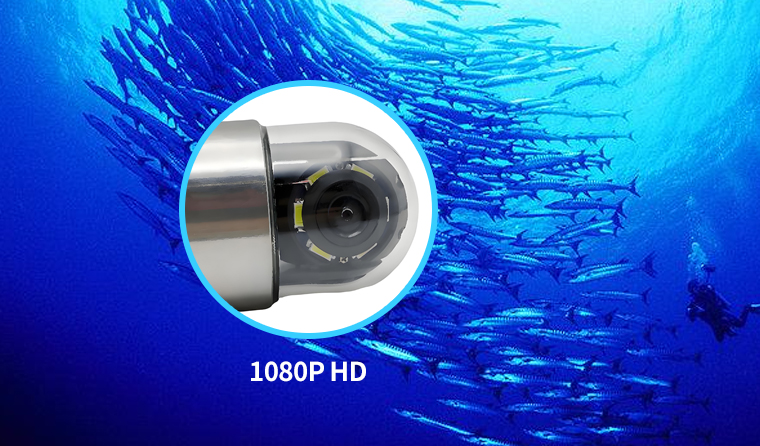

On the basis of ensuring that the pressure resistance performance meets the standards, the imaging quality of the underwater pressure-resistant camera is also indispensable, as clear images are the prerequisite for realizing fish behavior monitoring and growth status evaluation. Aquaculture monitoring needs to capture details such as fish feeding, swimming, and body shape changes. Therefore, the resolution of underwater pressure-resistant cameras should not be lower than 1080P. For refined monitoring (such as seedling growth observation), 4K ultra-high-definition resolution equipment can provide more delicate image quality. At the same time, the underwater environment is dimly lit and the water body is prone to turbidity. Underwater pressure-resistant cameras need to have excellent low-light imaging and fog penetration capabilities: equipment equipped with a large target surface low-illumination CMOS sensor can increase light intake in low-light environments and present clear images; products integrated with digital fog penetration algorithms can effectively reduce the scattering effect of suspended particles in the water on light, ensuring imaging clarity even in turbid water. In addition, the wide-angle lens equipped with some underwater pressure-resistant cameras can expand the monitoring field of view and reduce monitoring blind spots, which is especially suitable for panoramic monitoring of large-area deep-water aquaculture areas.

The installation method and fixing stability need to match the pressure resistance requirements and aquaculture scenarios to avoid affecting the pressure resistance performance or monitoring effect due to improper installation. For pond and shallow water aquaculture, bracket-fixed underwater pressure-resistant cameras can be used, which adapt to different water depths by adjusting the bracket height, while ensuring that the bracket material has anti-corrosion and pressure-resistant capabilities; in medium and deep water cage aquaculture, hoisting-type underwater pressure-resistant cameras should be selected, and the equipment is fixed on the cage frame through high-strength steel cables to prevent the equipment from shaking due to water flow impact and affecting image stability; deep-sea aquaculture scenarios require bottom-sitting or anchoring fixation, and the bottom of the equipment is equipped with a weighted base to ensure its stability in strong water flow and high-pressure environments. During installation, special attention should be paid to the pressure-resistant and waterproof treatment of the equipment connection wires—special underwater pressure-resistant cables are selected, whose outer armor protective layer can resist underwater pressure and mechanical wear, and have good waterproof performance to avoid equipment failure caused by wire damage.

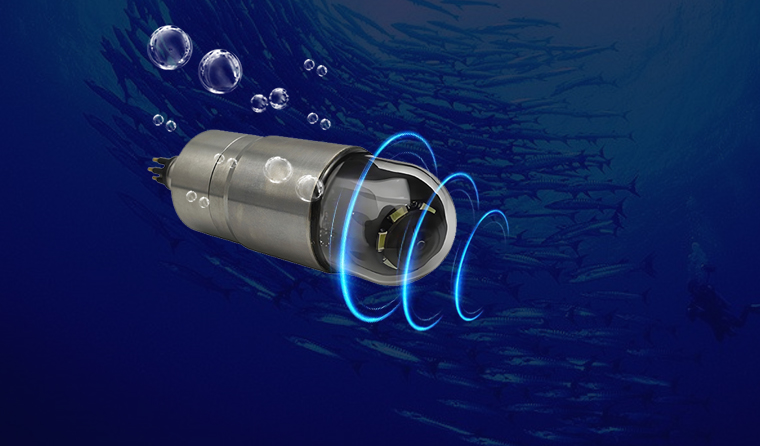

The stability and reliability of data transmission are key to the monitoring value of underwater pressure-resistant cameras. In deep water environments, wireless signals attenuate seriously, so the transmission method of underwater pressure-resistant cameras must be carefully selected: waterproof Wi-Fi modules can be used for wireless transmission in short-distance shallow water areas; underwater Ethernet or optical fiber transmission is recommended for medium and deep water areas—the former has stable high-speed data transmission capabilities, while the latter can effectively resist electromagnetic interference and is suitable for long-distance, high-bandwidth monitoring data transmission needs. In addition, underwater pressure-resistant cameras should support dual modes of local storage and cloud backup: local storage can be realized through a built-in large-capacity waterproof SD card to avoid data loss due to transmission interruption; cloud backup can upload monitoring images and data to the cloud platform in real time, allowing farmers to view remotely through computers, mobile phones and other terminals to grasp underwater aquaculture dynamics in a timely manner.

Intelligent functions can further enhance the aquaculture management value of underwater pressure-resistant cameras. Equipment with motion detection and abnormal alarm functions can immediately trigger sound and light alarms and push information to farmers' terminals when abnormal fish gathering, jumping or alien species invasion is detected; high-end underwater pressure-resistant cameras integrated with AI intelligent recognition can automatically identify fish species, quantity and growth stages, and judge fish growth status based on preset parameters, providing data support for feeding amount adjustment and aquaculture density optimization. Some equipment can also link with water quality sensors to simultaneously monitor parameters such as water temperature, dissolved oxygen, and pH value, realizing integrated management of "video monitoring + data monitoring" to help farmers comprehensively grasp the underwater aquaculture environment and biological status.

Finally, choosing an underwater pressure-resistant camera requires rational decision-making based on aquaculture scenarios and budgets. For conventional medium and shallow water aquaculture (10-30 meters), economical equipment with a rated working water depth of 50 meters, 1080P resolution, and basic waterproof and pressure-resistant performance can meet the needs; for deep-sea aquaculture or scientific research monitoring scenarios, high-end equipment with a rated working water depth of more than 100 meters, 4K ultra-high definition, AI intelligent analysis and optical fiber transmission functions must be selected to ensure stable operation in extreme environments. At the same time, priority should be given to brands with professional underwater equipment production qualifications and perfect after-sales service. When purchasing, it is required to provide pressure resistance performance test reports, and confirm that the brand can provide equipment installation guidance, regular maintenance, fault repair and other services to avoid affecting aquaculture monitoring work due to equipment quality or after-sales problems.

For more information about underwater aquaculture camera, please visit the homepage.