In modern aquaculture models such as deepwater cage farming and offshore ranching, underwater cameras have become core equipment for "visual management" — they can real-time monitor fish feeding and growth status, warn of risks such as cage damage and water quality deterioration, directly affecting aquaculture efficiency and economic benefits. However, the deepwater aquaculture environment features high salinity, large pressure fluctuations, turbid water, and frequent biological fouling, making ordinary underwater cameras unsuitable. When selecting dedicated deepwater aquaculture cameras, focus on the following 6 core considerations to ensure the equipment is "durable, clear, and usable".

I. Prioritize Matching Aquaculture Depth and Pressure Rating

Water depth directly determines the camera's pressure resistance, making it the primary prerequisite for selection. Different aquaculture scenarios vary significantly in water depth: nearshore deepwater cage farming is usually 10-30 meters deep, offshore ranching can reach over 50 meters, and special deep-sea aquaculture areas may even exceed 100 meters. When purchasing, clarify the equipment's rated water pressure (waterproof depth) and must reserve a safety margin — it is recommended to choose products with a rated waterproof depth 20%-30% higher than the actual aquaculture depth.

For example, in cage farming at 30 meters depth, prioritize cameras with a rated waterproof depth of 50 meters or more. Meanwhile, distinguish between "static waterproofing" and "dynamic waterproofing": static waterproofing is only suitable for fixed installation scenarios; if paired with underwater robots for mobile inspection, choose equipment with stronger dynamic waterproofing performance to avoid seal failure due to water flow impact and equipment movement. In addition, deep-sea aquaculture requires attention to whether the equipment has a pressure compensation function, which balances internal and external pressure through inert gas filling or elastic diaphragm design to prevent shell deformation and lens rupture.

II. Focus on Corrosion Resistance to Adapt to High-Salinity Aquaculture Environments

High salinity of seawater is the main cause of equipment corrosion, and long-term immersion can lead to shell rust and electronic component failure. Evaluate corrosion resistance from both "material and process" dimensions when selecting:

-

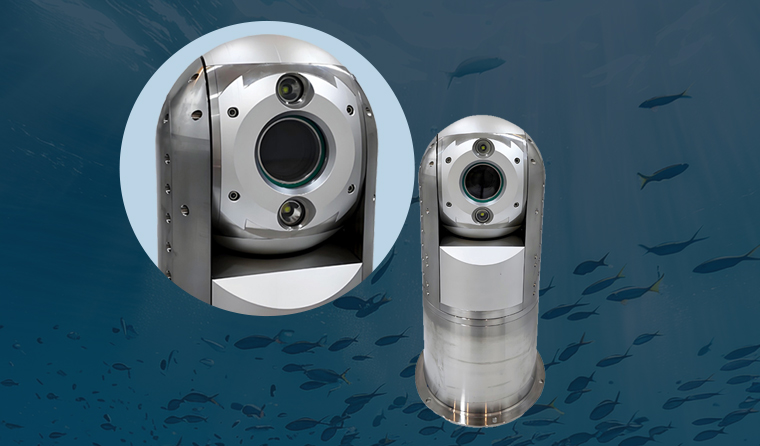

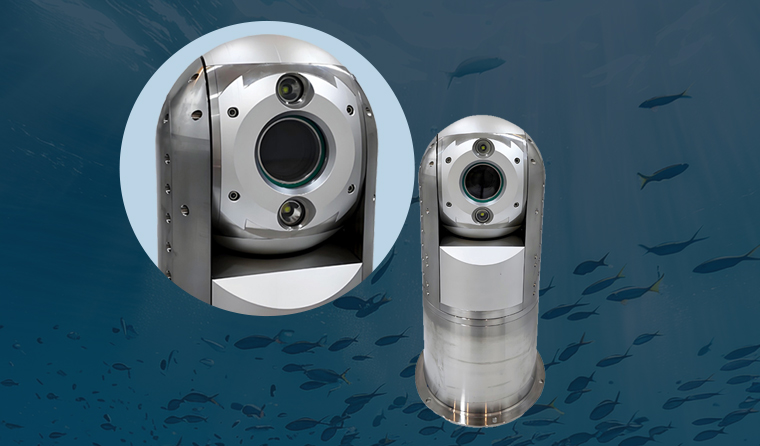

Shell Material: 316L stainless steel (containing molybdenum, resistant to chloride corrosion) can be used for aquaculture within 10 meters in shallow seas; for deepwater aquaculture above 10 meters, upgrade to titanium alloy (strong corrosion resistance, high strength, no rust after long-term immersion); for limited budgets, engineering plastics (such as PEEK, PPS, chemically corrosion-resistant but low strength, only suitable for fixed shallow water environments) are also optional.

-

Surface Treatment Process: Metal shells require anodizing, nickel-phosphorus alloy plating, etc., to form a dense protective film; the lens protection window should preferably be sapphire glass or zirconia ceramic, which combines corrosion resistance and high light transmittance.

-

Internal Protection: Core circuit boards need conformal coating treatment (covered with insulating resin), and key interfaces adopt hermetic packaging to prevent salt from seeping into and eroding components.

III. Imaging Performance Must Adapt to Aquaculture Water Characteristics

Deepwater aquaculture water often has problems such as low transparency, weak light, and abundant plankton. The camera's imaging performance directly affects monitoring results, so focus on the following parameters:

-

Resolution and Frame Rate: 1080P (1920×1080) resolution is sufficient for basic monitoring; to identify fish size and feeding details, upgrade to 4K (3840×2160) is recommended. The frame rate must be ≥25fps to avoid missed judgments of fish activity due to frame stuttering.

-

Low-Light Performance: Light is insufficient in deepwater environments, so choose starlight-level or blacklight-level sensors (sensitivity ≥0.01Lux) with large-aperture lenses (aperture ≤F1.2) to ensure clear color images in low light without relying on infrared supplementary light (infrared light may affect the behavior of some fish).

-

Anti-Fog and Decontamination Functions: Temperature differences in water can easily cause lens fogging; choose equipment with automatic anti-fog functions (such as heating defogging, anti-fog coating); for turbid water, prioritize cameras with Wide Dynamic Range (WDR) and 3D noise reduction functions to suppress stray light interference and improve image contrast.

IV. Functional Design Must Meet Aquaculture Management Needs

Dedicated deepwater aquaculture cameras need practical functions adapted to aquaculture scenarios to avoid "redundant functions" or "insufficient performance":

-

Real-Time Monitoring and Early Warning: Integrate water quality sensors (such as dissolved oxygen, pH, salinity, water temperature) to synchronously collect water quality data and automatically alarm when parameters exceed standards; support motion detection and regional intrusion alarm to promptly push early warning information when large marine organisms (such as sharks, sea lions) are found near cages or fish escape due to cage damage.

-

Installation and Maintenance Convenience: Considering the difficulty of deepwater operations, equipment should be designed with convenient installation structures (such as flange connections, quick buckles) and support multi-angle adjustment (360° horizontal rotation, -90°~+90° vertical); it is recommended to choose products with remote operation and maintenance functions, which allow remote parameter adjustment and firmware upgrades via mobile phones or computers, reducing the frequency of underwater operations.

-

Battery Life and Power Supply: Prioritize wired power supply (with waterproof cables) for fixed installation scenarios; for mobile inspection scenarios, pay attention to battery life — choose lithium batteries with a battery life of ≥8 hours, supporting fast charging and solar auxiliary power supply to adapt to long-term field aquaculture needs.

V. Stability and Compatibility Ensure Long-Term Use

The maintenance cost of deepwater aquaculture equipment is high, and stability and compatibility directly determine the service life and later expansibility:

-

Stability: Choose products that have undergone strict environmental testing (such as high-low temperature cycling, salt spray testing, vibration testing) to ensure stable operation within the water temperature range of -20℃~60℃; pay attention to brand after-sales service, and prioritize manufacturers that provide a warranty of more than 2 years and support on-site maintenance.

-

Compatibility: Equipment must support mainstream communication protocols (such as ONVIF, RTSP) and can be seamlessly connected to the aquaculture farm's video monitoring platform; if intelligent management needs to be expanded later, choose cameras that support AI algorithm integration, which can later load functional modules such as fish counting and feeding behavior analysis.

-

Anti-Biological Fouling: Barnacles and algae in deepwater environments easily attach to lenses and shells, affecting imaging and equipment heat dissipation. It is recommended to choose products with anti-biological fouling coatings (such as polytetrafluoroethylene coatings) or automatic cleaning devices (such as rotating scrapers) to reduce the frequency of manual cleaning.

For more information about underwater aquaculture camera, please visit the homepage.