How to Determine Whether the Waterproof Effect of Underwater Aquaculture Cameras is Qualified

Hits: 1048 Time: October 27,2025

The waterproof performance of underwater aquaculture cameras is a core indicator that determines their service life and monitoring stability. If the waterproof effect is not up to standard, it will not only cause short-circuit damage to the equipment but also interrupt the monitoring of the aquaculture environment, resulting in economic losses. The following provides practical methods to judge the waterproof effect from three stages: preliminary verification, on-site testing, and long-term observation, helping aquaculture practitioners accurately identify hidden risks.

Before installing the equipment, initially judge the waterproof capability through qualification verification and static testing to avoid using products with inherent waterproof defects.

-

Check the waterproof grade certification: Confirm whether the product is marked with the internationally recognized IP waterproof grade. For underwater aquaculture scenarios, it should reach at least IP68 (can be soaked in 1.5 meters of water for a long time), and IP69K or higher grades are required for special deep-water aquaculture. At the same time, check whether there is a waterproof performance report issued by a third-party testing organization to avoid relying solely on the manufacturer's self-promotion.

-

Conduct static water immersion test: Fully immerse the camera (including cable interfaces and junction boxes) in clean water. The water depth should simulate the actual installation depth, and the immersion time should be no less than 24 hours. During this period, check the appearance of the equipment every 6 hours to see if there are bubbles (bubbles may indicate air leakage from the shell or interface, posing a risk of water ingress). At the same time, power on the equipment to test whether the video signal is stable.

-

Check the integrity of waterproof components: Carefully check whether the camera lens seal ring and cable connector waterproof rubber ring are deformed, cracked, or aged. If the equipment is equipped with a waterproof and breathable valve, confirm that it is not blocked and can normally balance the internal and external air pressure (to prevent the shell from cracking due to temperature difference).

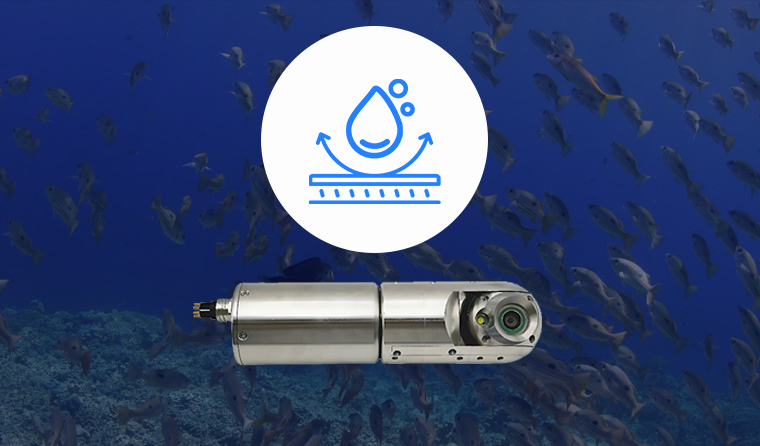

After the equipment is installed in the aquaculture water area, dynamic testing should be carried out in combination with actual working conditions to simulate the impact of environmental factors such as water flow and water pressure on the waterproof effect.

-

Water pressure impact test: For scenarios with rapid water flow such as cage aquaculture, a high-pressure water gun (pressure adjusted to 0.3-0.5MPa) can be used to flush the camera shell and interfaces for 30 seconds to simulate strong water flow impact. After the test, power off and disassemble the junction box to check whether there is water accumulation or moisture inside.

-

Underwater tightness observation: After installation, continue to observe for 3-7 days. Check the lens for water mist through the monitoring screen every day (water mist inside the lens indicates insufficient shell tightness and water vapor ingress). At the same time, regularly dive or use an underwater robot to approach the equipment to check whether there are water seepage traces at the cable connection or whether impurities in the aquaculture water (such as algae and sediment) adhere to the interface gaps (impurity accumulation may aggravate the wear of seals).

-

Electrical performance monitoring: Use the equipment's built-in current monitoring function (or an external ammeter) to observe whether the working current of the equipment is stable. If the current suddenly increases or fluctuates frequently, it may be that internal water ingress causes a short circuit. In this case, power off and remove the equipment immediately to check the waterproof condition.

The waterproof effect will gradually decline with the increase of service time, so long-term observation is needed to detect potential problems in a timely manner.

-

Regular disassembly and inspection: Remove the camera from the water every 3-6 months, disassemble components such as the junction box and lens cover, and check whether there is water accumulation, rust, or mold inside (water accumulation will corrode the circuit board, and mold will damage the seals). Focus on checking whether the waterproof tape or sealant at the connection between the cable and the equipment is aged and cracked.

-

Special testing after severe weather: After extreme weather such as heavy rain and typhoons, increase the frequency of waterproof inspections. Heavy rain may cause the water level of the aquaculture water area to rise sharply and increase water pressure; typhoons may displace the equipment and deform the sealing components under force, which may damage the waterproof effect. Timely inspection and repair are required.

-

Compare changes in monitoring effect: If the monitoring screen is found to be continuously blurred or the color is distorted, and the lens pollution factor is excluded, it may be that the waterproof function fails and causes the internal components to be damp. At this time, stop using the equipment immediately, disassemble and check the waterproof condition to avoid expanding the fault.

For more information about underwater aquaculture camera, please visit the homepage.