As a core device for visual monitoring in aquaculture, the performance and service life of underwater aquaculture cameras depend not only on the equipment's own performance but also on operations such as installation and commissioning, environmental adaptation, and daily maintenance. To ensure stable operation of the equipment and accurate acquisition of monitoring data, the following key precautions are summarized from four dimensions: environmental adaptation, installation and commissioning, operation and maintenance, and safety protection.

I. Environmental Adaptation: Accurately Matching the Characteristics of Aquaculture Scenarios

The underwater aquaculture environment is complex and changeable, and factors such as water quality, water temperature, and water pressure directly affect the operation of the equipment. It is necessary to evaluate in advance and adapt accordingly.

1. Water Quality Adaptation: Balancing Cleanliness and Corrosiveness

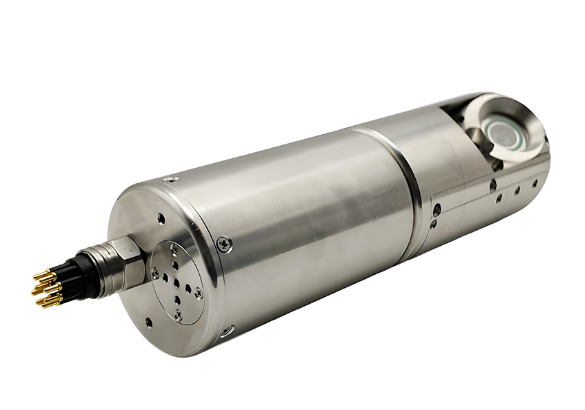

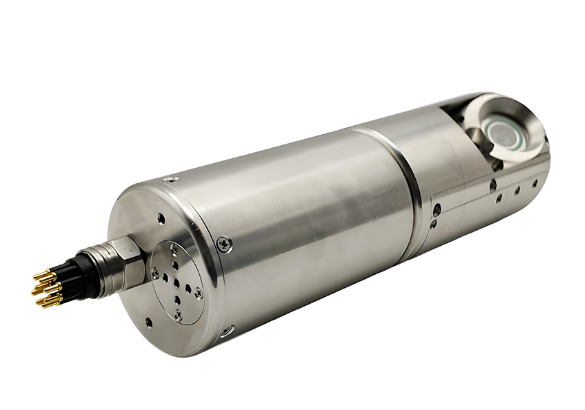

Different aquaculture water bodies have significant differences in turbidity and corrosiveness, and it is necessary to give priority to equipment with corresponding protection levels. For freshwater environments such as ponds and reservoirs, the water turbidity is usually 0.5-1.5 meters, and a model with basic waterproofing (IP68 or above) and a stainless steel shell can be selected; for scenarios such as marine cages and tidal flats, due to the high salinity of 20-35‰ and strong corrosiveness, a special model with a titanium alloy shell + anti-marine corrosion coating must be used, and the lens seal must be made of salt-resistant materials such as fluororubber to avoid water leakage after long-term immersion. In addition, for estuary aquaculture environments with high sediment content, an additional sediment-proof lens cover must be equipped to prevent lens abrasion or blockage.

2. Water Depth and Pressure: Strictly Matching the Pressure Resistance Level

Water pressure is one of the main causes of equipment damage. It is necessary to select a model with a corresponding pressure resistance level according to the actual aquaculture water depth and reserve a safety margin. For shallow water environments (≤5 meters, such as industrial aquaculture tanks and shoals), a 5-meter pressure-resistant model can be used; for medium-deep water environments (5-30 meters, such as offshore cages and deep-water ponds), a 10-30 meter pressure-resistant model is required. Its shell is mostly made of thickened engineering plastic or metal materials, and some support depth adjustment via cables; for deep water environments (>30 meters, such as deep-sea cages and marine pastures), a professional model with 50-100 meters pressure resistance is required, usually used with a Remotely Operated Vehicle (ROV). It is particularly important to confirm the actual water depth of the aquaculture area in advance, including the depth change caused by tidal fluctuations, and reserve a 10%-20% pressure resistance margin to avoid equipment damage caused by extreme conditions.

3. Temperature, Humidity and Light: Adapting to Extreme Environments and Imaging Needs

In terms of water temperature, conventional models have an operating temperature of 0℃-40℃, which can cover most aquaculture scenarios in temperate and subtropical regions; under-ice aquaculture in northern winters requires a low-temperature start-up model (with an operating temperature lower limit of -5℃ or below) to prevent circuit damage; aquaculture in tropical summers requires a model with a high-temperature resistance and heat dissipation design to avoid overheating of the main board. In terms of light, a model with Wide Dynamic Range (WDR) should be selected for open-air aquaculture scenarios during the day to reduce overexposure caused by strong light reflection; for night, deep water or indoor aquaculture tanks, a model with infrared fill light (fill light distance of 3-10 meters) or white light fill light (fill light distance of 2-5 meters) should be used. Among them, infrared fill light is suitable for non-interference monitoring, and white light fill light is suitable for scenarios requiring color images for fish health inspection.

II. Installation and Commissioning: Standardized Operation to Improve Monitoring Effect

Scientific installation and commissioning are key to ensuring stable operation of the equipment and accurate data. It is necessary to focus on the installation location, fixing method, and parameter setting.

1. Installation Location: Avoid Interference Sources and Cover Core Areas

During installation, it is necessary to stay away from equipment such as aerators and water pumps to avoid image shaking caused by water flow impact; the lens should face the center of the aquaculture area to ensure coverage of core monitoring areas such as fish school feeding and swimming. For cage aquaculture, the equipment can be fixed on the cage frame at a height of 1-2 meters from the bottom of the cage to monitor both upper and middle fish schools; for industrial aquaculture tanks, it can be installed in the middle of the tank wall to avoid obstacles such as pipelines and brackets. In addition, in marine aquaculture scenarios, the installation height of the equipment should be higher than the activity area of the aquaculture organisms to prevent damage caused by collisions with large fish, shrimp, and crabs.

2. Fixing and Wiring: Ensuring Stability and Corrosion Resistance

The fixing method should be adjusted according to the scenario. For shallow water environments, bracket fixing or tank wall embedded installation can be used; for medium-deep water environments, an anti-shaking bracket with a buoyancy adjustment device is required to resist equipment shaking caused by wind and waves. During wiring, the underwater cable should be a special cable with corrosion resistance and tensile strength. The interface should be double-sealed and wrapped with waterproof tape to prevent moisture from seeping in. In deep water scenarios, if the cable length exceeds 10 meters, a signal amplifier must be equipped to prevent video signal transmission attenuation.

3. Parameter Commissioning: Optimizing Imaging and Monitoring Accuracy

After installation, it is necessary to adjust parameters such as lens focal length and fill light intensity to ensure clear imaging. When natural light is sufficient during the day, adjust the wide dynamic range parameters to balance the brightness of the strong light area and the shadow area; when the fill light function is turned on at night, adjust the fill light intensity according to the water depth to avoid over-brightness causing image whitening or over-darkness failing to capture details. For scenarios requiring long-term monitoring, scheduled capture or video recording parameters can be set, and the monitoring frequency can be adjusted according to the aquaculture cycle. For example, increase the monitoring frequency during the feeding peak period and reduce it during the dormant period to save storage resources.

III. Operation and Maintenance: Regular Maintenance to Extend Equipment Service Life

Daily maintenance is key to reducing equipment failure rates. A regular inspection and cleaning mechanism must be established to deal with potential problems in a timely manner.

1. Regular Cleaning: Removing Attached Contaminants

Algae, shellfish, sediment, etc. in the water are easy to attach to the lens and shell, affecting the imaging effect. It is necessary to clean at least once a month. When cleaning, freshwater aquaculture equipment can be directly rinsed with clean water on the lens and shell; marine aquaculture equipment must be thoroughly rinsed with freshwater to remove salt residues, and then the lens is wiped with a soft cloth to avoid scratching the tempered glass surface. For models with automatic cleaning functions, it is necessary to regularly check the operation status of the cleaning device (such as rotating scraping, high-pressure water flushing) to ensure its normal operation.

2. Component Inspection: Troubleshooting Wear and Hidden Dangers

The equipment components must be fully inspected every quarter, focusing on whether the shell has scratches or deformation, whether the seal ring is aging or cracked, and whether the cable interface is loose or rusted. If the shell is damaged, it must be repaired or replaced in a timely manner to prevent water from seeping in; if the seal ring is aging, it must be replaced immediately to avoid waterproof failure; if the interface is loose, it should be re-tightened and wrapped with waterproof tape. In addition, regularly check the operation status of the fill light device and signal transmission module, and debug or repair in a timely manner if problems such as flickering and freezing are found.

3. Data Management: Ensuring Storage and Transmission Security

Regularly back up monitoring data to avoid data loss caused by equipment failure or storage medium damage. For equipment with local storage, it is necessary to regularly replace the memory card and export data; for equipment with cloud storage, it is necessary to check the stability of network transmission to ensure real-time data upload. At the same time, set data access permissions to prevent leakage of sensitive monitoring data (such as aquaculture density and growth status).

IV. Safety Protection: Balancing Equipment and Aquaculture Safety

During use, it is necessary to balance equipment safety and aquaculture biological safety to avoid mutual interference.

1. Preventing Biological Interference: Avoiding Attachment and Collision

For scenarios where shellfish and algae are easy to attach, a silicone-based anti-attachment coating can be applied to the equipment surface, or a model with a regular automatic cleaning function can be selected; for high-density fish aquaculture scenarios (such as tuna and cod cages), a model with an impact-resistant shell should be selected, and the lens should be made of tempered glass to prevent damage caused by collisions with large fish. At the same time, avoid direct contact between the equipment and aquaculture seedlings to prevent physical damage.

2. Electrical Safety: Standardizing Power Supply and Grounding

The equipment power supply should use a stable DC power supply to avoid circuit damage caused by voltage fluctuations; in conductive environments such as seawater, the equipment must be grounded to prevent safety accidents caused by electric leakage. Regularly check whether the power supply line is aging or damaged, and replace it in a timely manner if problems are found to avoid short circuits or electric leakage.

V. Emergency Handling: Responding Quickly to Sudden Failures

If problems such as failure to start, blurry images, or signal interruption occur, troubleshooting should be carried out according to the process. First, check the power supply line and interface to confirm whether the power failure is caused by poor contact; second, check whether the lens is attached with contaminants and observe the imaging effect after cleaning; if the signal is interrupted, check whether the signal amplifier is normal in deep water scenarios, and try to restart the equipment or reconnect to the network in shallow water scenarios. If the fault cannot be solved on-site, the equipment should be disassembled in a timely manner and professional personnel should be contacted for maintenance to avoid aggravated damage caused by long-term immersion.

In conclusion, the use of underwater aquaculture cameras should follow the full-process logic of "environmental adaptation - standardized installation - regular maintenance - emergency handling". Select equipment and operate scientifically in combination with the characteristics of specific aquaculture scenarios to maximize its monitoring value and provide reliable support for the refined management of aquaculture.

For more information about underwater aquaculture camera, please visit the homepage.